Why Select Expert Welding Inspection Gilbert Arizona for Your Jobs?

Welding Examination Demystified: Trick Procedures, Tools, and the Important Function They Play in Keeping High-Quality Welds

Welding assessment offers as a vital foundation in the assurance of structural stability and quality in bonded joints, impacting different industries from building and construction to production. This procedure is not simply a formality; it encompasses important strategies such as aesthetic exams and progressed non-destructive screening techniques created to discover issues that could compromise safety. With an array of specialized tools at their disposal, inspectors play a vital duty in keeping high standards. Yet, the intricacies of these methods and their effects for quality control continue to be usually neglected. What are the key procedures and tools that guarantee these requirements are supported?

Significance of Welding Inspection

Making sure the integrity of bonded joints is critical in numerous markets, making the relevance of welding evaluation obvious. The high quality of welds straight impacts the safety and security, efficiency, and longevity of elements and structures. In fields such as construction, automotive, aerospace, and production, any type of failing in welded joints can lead to devastating consequences, including structural failures, tools malfunction, and loss of life.

Welding evaluation acts as a vital quality assurance measure, making sure that welds meet specified criteria and regulatory requirements. It determines defects such as fractures, porosity, and insufficient fusion that might endanger the toughness of the weld. By finding these concerns early, welding inspection can avoid pricey rework, delays, and prospective safety dangers.

Moreover, welding assessment cultivates conformity with industry requirements and certifications, boosting the reputation of organizations and their items. It additionally supports continuous renovation by offering valuable responses to welding personnel, allowing them to fine-tune their procedures and strategies.

Ultimately, the value of welding evaluation can not be overemphasized; it is crucial for maintaining top notch welds, guaranteeing safety, and protecting investments throughout numerous sectors.

Key Evaluation Processes

Reliable welding inspection depends on a series of essential procedures created to review the top quality and honesty of welds. These procedures include both aesthetic and non-destructive testing (NDT) methods, making sure that any issues are recognized before they compromise architectural integrity.

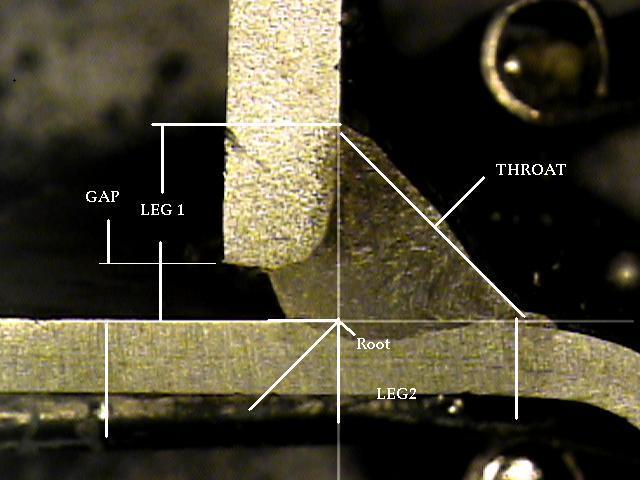

The first action in the assessment process is a complete aesthetic examination, which permits inspectors to analyze welds for surface area problems such as splits, damages, and insufficient combination. Complying with visual checks, various NDT techniques may be used, including ultrasonic screening, magnetic fragment testing, and radiographic screening. Each technique uses one-of-a-kind benefits; as an example, ultrasonic testing can spot inner flaws, while radiographic testing offers a permanent document of the weld's inner framework.

Furthermore, it is essential to confirm conformity with relevant codes and standards, making sure that the weld fulfills industry specs. This consists of checking weld dimensions and positioning, as improper measurements can lead to failings under tons.

Essential Tools for Assessment

Frequently using the right tools is crucial for accomplishing precise welding inspections. A comprehensive set of examination tools assists make sure that welds meet rigid top quality requirements and requirements.

Among the primary devices is the visual evaluation gauge, which allows inspectors to assess surface area problems, such as sanitation and surface area coating, straight. Additionally, micrometers and calipers are crucial for gauging weld dimensions and ensuring they adhere to required tolerances.

For even more detailed analyses, ultrasonic screening (UT) equipment is important. This technique makes use of high-frequency acoustic waves to identify internal defects and examine product thickness. Magnetic particle screening (MT) their explanation and dye penetrant screening (PT) are crucial for identifying surface area and near-surface issues, supplying instant aesthetic indications of prospective problems.

Welders must additionally be outfitted with hardness testers, which examine the mechanical residential or commercial properties of the weld steel and base products, guaranteeing they fulfill given demands. Finally, recording findings with electronic assessment tools improves traceability and quality assurance. By utilizing these crucial tools, inspectors can preserve top quality welds, inevitably adding to the safety and integrity of welded frameworks.

Common Defects and Their Discovery

Welds, similar to the foundation of architectural honesty in construction and production, can exhibit numerous defects that endanger their efficiency and security. Common issues consist of porosity, cracks, undercut, absence of combination, and slag inclusions (Welding Inspection Gilbert Arizona). Each of these imperfections can materialize due to inappropriate welding strategies, bad material option, or insufficient prep work

Discovery of these flaws can be accomplished with various non-destructive testing approaches, consisting of aesthetic examination, ultrasonic screening, and radiographic testing. Each method plays a vital role in recognizing these mistakes, making certain that the stability of the weld is maintained and decreasing the risk of failing in important applications.

Best Practices for Quality Assurance

Guaranteeing the best quality of welds is critical for structural honesty and security, especially in sectors where the effects of failing can be extreme. To accomplish this, a number of finest methods for quality guarantee need to be carried out throughout the welding procedure.

First, a durable welding procedure requirements (WPS) need to be established, describing the required criteria for every welding procedure. This guarantees click to investigate uniformity and adherence to industry requirements. Second, extensive training and accreditation of welders are essential; knowledgeable workers are better equipped to produce premium welds and acknowledge possible issues.

Regular evaluations need to be incorporated into the welding procedure, using both non-destructive and visual screening (NDT) approaches to discover flaws beforehand. Regular calibration of examination devices is important to preserve accuracy. Furthermore, recording all welding activities, consisting of inspections and restorative actions, produces a deducible document that can be important for high quality control.

Final Thought

To conclude, welding inspection works as an essential device for guaranteeing the stability and dependability of bonded joints throughout industries - Welding Inspection Gilbert Arizona. With the execution of essential assessment processes and the application of vital tools, organizations can efficiently recognize and resolve potential problems. Adherence to ideal methods in top quality guarantee not only boosts security but additionally guarantees compliance with market standards, ultimately contributing to the longevity and efficiency of frameworks and elements

Welding evaluation serves as an essential foundation in the assurance of structural integrity and quality in bonded joints, influencing numerous markets from building to production.Making certain the integrity of welded joints is extremely important in numerous markets, making the significance of welding evaluation obvious.Welding assessment serves as a crucial quality control action, guaranteeing that welds meet specified standards and regulatory demands. By using these important devices, examiners can keep top notch welds, eventually adding to the security and reliability of bonded structures.

In conclusion, welding evaluation offers as an essential mechanism for ensuring the stability and reliability of welded joints throughout markets.